The Vibco Gyrator screen is a screening device that vibrates about its centre axis using a vibrator motor as a power source. The motor and screen assemble are rigidly constructed together and isolated from the base using rubber mounts.

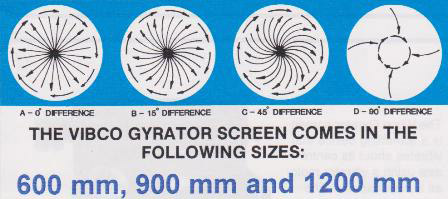

Vibration is generated by two eccentric weights on the upper and lower ends of the motor shaft. The top weight controls the vibration in the horizontal plane, and causes the material to cross the screen cloth. The lower weight acts to tilt the machine giving vibration in the vertical plane. The difference in angle between the weights induces variable control for the screening pattern.

The Vibco Gyratory screen comes in the following sizes: 600 mm, 900 mm and 1200 mm

Available in single, double and triple deck units. Other units are available on special design.

The Vibco gyrator screens are very applicable for the following applications:

(a) Dry screening and classification down to 150 microns.

- Food industry

- Chemical industry

- Metal processing industry

- Wood products industry

- Pharmaceutical industry

- Fertiliser industry

- Abrasives industry

(b) Wet screening and classification.

- Pulp and paper industry

- Ceramics

- Waste disposal

- Paint industry

- Sugar and syrup

The above are some guidelines where the gyrator screens can be used. Vibco engineers can design special units to meet special applications if so required. If you have a screening problem, contact us as we have a wealth of knowledge on screening available.

Vibco also makes numerous other types of screens, which include horizontal and decline frame types.