Vibco Vibratory Hopper Dischargers are based on many years experience in the successful application of vibratory technology in materials handling, and the latest advances in the field. They are designed to use powerful vibratory forces to fluidize and provide continuous flow of the most sticky, self-binding, or bridging prone materials in hoppers, bins, and vertical chutes.

- Ensures effective continuous flow of difficult materials from hoppers, bins, silos and vertical chutes.

- Powerful maintenance free vibratory motors give long, trouble-free life.

- Rugged, heavy duty construction in mild or stainless steel to suit wide range of materials.

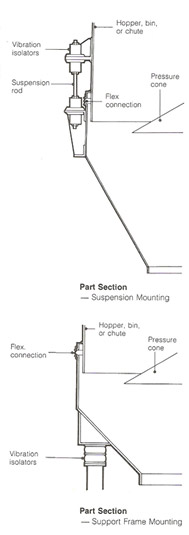

- Arranged for suspension or support frame mounting on reliable, efficient isolation mounts giving low noise.

Features

- Vibratory Motors - All vibco Vibratory Hopper Discharge are powered by long-life, maintenance-free, high quality motors.

- Vibration Isoloation - Whether suspended from hopper or bin, or mounted on a free-standing support frame, the vibratory forces are completely isolated from existing equipment.

- Internal Pressure Cone - Fitted within the unit, the pressure Cone relieves the lateral pressures whilst transmitting the vibratory forces into the main hopper or bin.

Applications

Manufactured in mild or stainless steel, Vibco Vibratory Hopper Dischargers are suitable for use with a wide range of powdered, granular, flaked or lumpy materials which have proved difficult to move out of containers, e.g. coal, wood chips, chemicals, ores, filter cakes, food products, sugars, fine powders etc.